Table of Contents

Laguna 20" Disc Grinder

(Please check contents against actual manual if available)

- Model: MSAN20DISC1PH2HP-020

- Manufacturer: Laguna

A disc sander consists of a replaceable circular shaped sandpaper attached to a wheel turned by an electric motor. The work piece is sat on a front bed that can be adjusted to various angles, and shaped accordingly.

The Tool Safety, Tool Care, Operation, section of this guide are what instructors use to ensure that you can use the equipment according to community expectations.

Requirements

General Metal Working clearance or class equivalent is required before use.

Warnings

🚫 Do not stand on the machine. Serious injury could occur if the machine tips over. Do not wet grind or polish.

🚫 Never use a steady stream of water on the workpiece. Only quench the workpiece in water to cool it.

🚫 Do not grind or polish magnesium as it may catch on fire.

⚠️ Replace sanding discs when they become loaded and glazed or frayed.

See the Safety Section for more information.

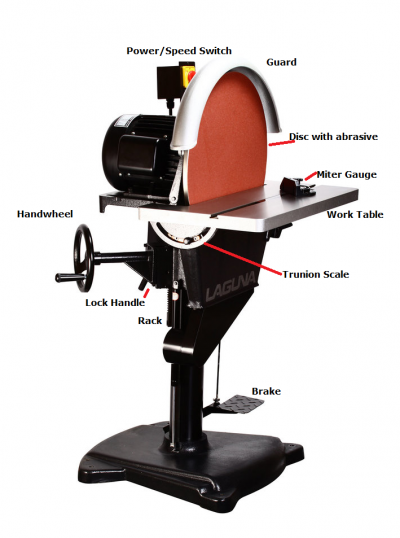

Tool Anatomy

- Guard

- Disc with abrasive

- Miter gauge

- Work Table

- Trunion Scale

- Brake

- Rack

- Lock Handle

- Hand wheel

- Power/Speed Switch

For more visit the manufacturers website and user manual both linked at the top of this document.

Tool Safety

Safety

Personal Protective Equipment

⚠️ Safety glasses, hearing protection, and nonskid closed-toed shoes are required.

⚠️ Remove tie, rings, watches and other jewelry, and roll sleeves up past the elbows.

⚠️ All hair, clothing and accessories should be secured close to the body.

🚫 Do not wear gloves.

Common Hazards

Pull/Abrasion Risk

- Keep safety guards in place at all times when the machine is in use. If removed for maintenance purposes, use extreme caution and replace the guards immediately.

- Maintain a balanced stance at all times so that you do not fall or lean against moving parts. Do not over-reach or use excessive force to perform any machine operation.

- Never leave the machine running unattended. Turn the power off and do not leave the machine until it comes to a complete stop.

- Make all machine adjustments or maintenance with the machine unplugged from the power source.

Flying Debris

- Support the workpiece with the miter gauge; maintain control of the workpiece at all times.

- After turning switch to “ON,” always allow the disc to come up to full speed before sanding or grinding. Keep hands clear of the disc.

Tool Care

Cleaning

- Turn off the machine and disconnect from power before cleaning.

- Use a brush or compressed air to remove chips or debris — do not use your hands.

Inspection

Before you start using the sander you are expected to do an initial inspection and assess its readiness for use.

- Make certain the switch is in the OFF position before connecting the machine to the power supply.

- Make all machine adjustments or maintenance with the machine unplugged from the power source.

- Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting wrenches are removed from the machine before turning it on.

- Check damaged parts. Before further use of the machine, a guard or other part that is damaged should be carefully checked to determine that it will operate properly and perform its intended function. Check for alignment of moving parts, binding of moving parts, breakage of parts, mounting and any other conditions that may affect its operation. A guard or other part that is damaged should be properly repaired or replaced.

Operation

Raise the table into position. After turning on the sander, allow the disc to come up to full speed before beginning to sand.

Forward-Reverse Switch

When changing direction with the Forward-Reverse switch, turn the lever to the OFF position and allow the disc to come to a complete stop. (Use the brake for immediate stop). Then turn the lever to the opposite direction, and allow the disc to come up to speed.

Brake

⚠️ Apply the brake only when the switch is OFF. Damage to the machine can occur if the brake is applied while the switch is ON.

* Pull the brake handle until the pad contacts the rotating disc.

Maintenance Requests

If you encounter any of the issues listed in the Inspection area or have any other issues with the printer not working properly

- Update the physical Maintenance Tag at the machine

- 🟢Green can be used without issue

- 🟡Yellow can be used withcaution

- ⛔Red cannot be used without hazard to either the user or the equipment

- Record issues at protohaven.org/maintenance. This notifies our staff and volunteer maintenance crew of any issues.

Troubleshooting

| Trouble | Probable Cause | Remedy |

|---|---|---|

| Machine will not start/restart or repeatedly trips circuit breakers or blows fuses. | Machine not connected to power source. | Verify machine is connected to power. |

| Fuse blown, or circuit breaker tripped. | Replace fuse, or reset circuit breaker. | |

| Cord damaged. | Replace cord. | |

| Extension cord too light or too long. | Use adequate size extension cord. | |

| Building circuit breaker trips or fuse blows. | Verify that sander is on a circuit of correct size. If circuit size is correct, there is probably a loose electrical lead. | |

| Loose electrical connections. | Go through all the electrical connections on the edge sander including motor connections, verifying the tightness of each. Look for any signs of electrical arcing which is a sure indicator of loose connection or circuit overload. | |

| Switch or motor failure (how to distinguish). | If you have access to a voltmeter, you can separate a switch failure from a motor failure by first, verifying incoming voltage at 220+/-10% and second, checking the voltage between switch and motor at 220+/-10%. If incoming voltage is incorrect, you have a power supply problem. If voltage between switch and motor is incorrect, you have a switch problem. If voltage between switch and motor is correct, you have a motor problem. | |

| Motor failure. | If electric motor is suspect, you have two options: Have a qualified electrician test the motor for function or remove the motor and take it to a qualified electric motor repair shop and have it tested. | |

| On/Off switch failure. (or Forward/Reverse switch on 3 phase model). | If the switch is suspect, you have two options: Have a qualified electrician test the switch for function, or purchase a new switch and establish if that was the problem on changeout. | |

| Disc won’t come up to speed. | Extension cord too light or too long. | Use adequate size extension cord. |

| Low (incoming) voltage. | Contact qualified electrician. | |

| Excessive bite, or feed pressure too great. | Allow sanding disc to cut freely, do not force. | |

| Excessive replacement of sanding paper. | Too much pressure being used during cuts. | Reduce pressure. |

| Not using full width of belt. | Stroke across the belt using full width. | |

| Machine vibrates excessively. | Sander base not level with floor. | Shim if necessary. |

| Not secured to the floor. | Use lag screws through holes in base to secure machine to the floor. | |

| Improper motor mounting. | Check and adjust mounting. | |

| Sanding marks on workpiece. | Sanding paper too coarse for required finish. | Use proper grit. Coarser grits for stock removal, and finer grits for finish work. |

| Workpiece sanded across grain. | When surface sanding, use fine sanding disc paper then finish by hand, working in direction of grain. | |

| Sanding grains quickly rub off paper. | Sanding paper has lost its original properties. | Do not store sanding paper in extremely dry or high temperature areas. Do not fold sanding disc papers, store them flat. |

| Sanding paper becomes glazed. | Sanding painted surface. | Use open-end grain/flint sanding paper. |

| Wood is wet or gummy. | No cure. Use different stock. | |

| Burn marks on workpiece. | Wrong sanding paper surface. | Use coarser grit for stock removal. |

| Feed pressure too great. | Do not force workpiece into disc. Use just enough pressure, and let the sanding disc do the work. | |

| Sanding paper burns, or clogs quickly. | Too much pressure, sanding disc biting too deeply into workpiece. | Adjust for slight sanding action and make several passes. |

| Workpiece pulled from hand. | No support for workpiece. | Use miter gauge. Keep workpiece firmly down against table. |

| Sanded edge is not square. | Result of freehand sanding. | Keep workpiece flat on table at all times when a square edge is desired. Use miter gauge to ensure workpiece is square with sanding disc. |

| Table scale inaccurate. | Check table alignment to disc with a machinist’s square. It should be 90 degrees. Adjust pointer and table angle if necessary. |

Additional Resources

Staff Use

| ⚠️ AUTHORIZED MAINTENANCE GROUP ONLY |

If you are part of the maintenance group please log on to the #maintenance channel of our Discord server to:

- Perform a Maintenance Action

- Request a Maintenance Purchase

- Review complete Maintenance Logs for each machine

- Generally chit-chat about maintenance

Tools

The following should be in a Maintenance tool kit for the….

- item1

- item2

Regular Maintenance

- Periodically, make sure the rack and the trunnions on both sides of the table are lubricated with a good grade, non-hardening grease.

- The table surface must be kept clean and free of rust for best results. If rust appears, remove it using a mixture of household ammonia, a good commercial detergent and #000 steel wool. Alternatively, commercial rust removers can be found at many hardware stores.

- Apply a light, protective coating over the table, such as paste wax. Products in aerosol form are also available in hardware stores and supply catalogs. Whatever method is chosen, the coating should protect the metal and provide a smooth surface, without staining the workpiece.

Replacing Abrasive Disc

- The grinder accepts standard 20” diameter cloth or paper-back sanding discs.

- Lower the table as far as possible, and push back the guard.

- Use a putty knife to remove the old abrasive from the disc. Clean the disc with solvent and allow it to dry.

- Mount the new sanding paper. Sanding paper is available in various forms, such as adhesive backed discs and pressure-sensitive discs.

- Raise the table, and pull the guard back over the disc before operating the sander.

Miter Gauge Alignment

The miter gauge is equipped with individually adjustable index stops at 90 degrees and 45 degrees right and left. The index stops can be adjusted by loosening the hex nut and turning the screw.

- Check the accuracy of the 90-degree stop by placing a square against the miter gauge and the disc.

- To operate the miter gauge, loosen knob and move the body of the miter gauge to the desired angle. Re-tighten knob before sanding operation.

- The miter gauge body is set to stop at 0 degrees and 45 degrees left or right. To move the gauge body beyond these points, the stop must be flipped out of the way.

Squaring the Table

- Verify the accuracy of the scale pointer by positioning the table in horizontal position, and placing a square on the table and flush against the disc. (It is easier to do this without an abrasive disc attached.)

- Adjust the table until the square is flush against both surfaces.

- If required, adjust the pointer to the zero mark, and retighten the screw.