Table of Contents

18-Gauge Narrow Crown Pneumatic Stapler (Please check, esp maintenance sections)

- Model: Porter Cable NS 100A

- Manufacturer: Porter Cable

- Manual: Download

Narrow crown construction staplers are used for cabinets, casebacks, drawers, insulation sheathing, underlayment, molding and trim. Unlike larger staplers designed to go around cables or wire without penetrating, a narrow crown stapler fastens material flush. It is best used on materials softer than hardwoods like oak.

The Tool Safety, Tool Care, Operation, section of this guide are what instructors use to ensure that you can use the equipment according to community expectations.

Requirements

Crown Stapler can be used without a clearance.

Warnings

🚫 Never connect to an air source that is capable of exceeding 175 PSI.

🚫 Only use an air hose that is rated for a maximum working pressure of at least 150 psi (10.3 bar) or 150% of the maximum system pressure, whichever is greater.

🚫 Keep hands and body parts clear of immediate work area.

🚫 Do not drive fasteners near edge of material, on top of other fasteners, at too great of an angle, or with the grain.

⚠️ Wear appropriate PPE.

⚠️ Remove finger from the trigger when not driving fasteners.

⚠️ Disconnect the tool from the air supply when a. Unattended, b. Performing any maintenance or repair, c. Clearing a jam, d. Moving the tool to a new location.

See the Safety Section for more information.

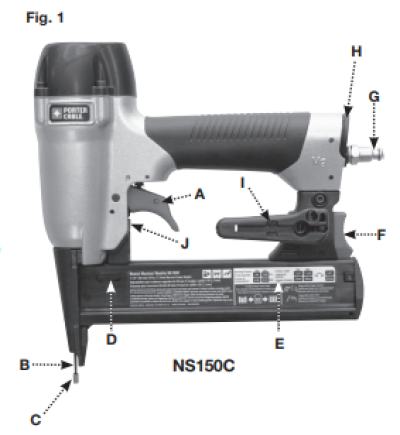

Tool Anatomy

A. Trigger

B. Contact trip

C. No-mar pad

D. Low nail indicator window

E. Magazine

F. Magazine Release

G. Air Inlet

H. Rear exhaust

I. Adjustable belt hook

J. Depth adjustment wheel

For more visit the manufacturers website and user manual both linked at the top of this document.

Tool Safety

Personal Protective Equipment

⚠️ Safety glasses, hearing protection, heavy duty gloves, and closed-toed shoes are required.

⚠️ All hair, clothing and accessories should be secured close to the body.

Common Hazards

Unintentional Firing

- Be sure the trigger is released before connecting to the air supply.

- Keep fingers away from trigger when not firing.

- Always assume the tool contains fasteners.

Double Firing

- When using the bump action trigger, be careful of unintentional double fires resulting from tool recoil. Unwanted fasteners may be driven if the contact trip is allowed to accidentally re-contact the work surface.

To Avoid Double Fires:

- Do not engage the tool against the work surface with a strong force.

- Allow the tool to recoil fully after each actuation.

- Use sequential action trigger.

- When bump actuating the nailer, always keep tool in control. Inaccurate placement of tool can result in misdirected discharge of a fastener.

Protruding Fasteners

- Drive the nail perpendicular to the grain to reduce risk of unexpected protrusion.

- Be aware that when the tool is being utilized at pressures on the high end of its operating range, nails can be driven completely through thin or very soft work material. Be aware of material thickness and set depth appropriately.

- Always disconnect air supply and avoid contact with trigger during depth adjustments.

Tool Care

Care

Disconnect the tool from the air supply and remove fasteners from magazine before making adjustments or personal injury may result.

Daily Maintenance

| Action | Why | How |

|---|---|---|

| Drain compressor tanks and hoses daily. | Prevents accumulation of moisture in compressor and nailer. | Open petcocks or other drain valves on compressor tanks. Allow any accumulated water to drain from hoses. |

| Clean magazine, magazine release and contact trip mechanism. | Permits smooth operation of magazine, reduces wear and prevents jams. | Blow clean with compressor air. The use of oils, lubricants periodically or solvents is not recommended as they tend to attract debris. |

| Before each use, check to insure all screws, nuts and fasteners are tight and undamaged. | Prevents jams, leaks and premature failure of tool parts. | Tighten loose screws or other fasteners using the appropriate hex wrench or screwdriver. |

Cleaning

Never use solvents or other harsh chemicals for cleaning the non-metallic parts of the tool. These chemicals may weaken the materials used in these parts. Use a cloth dampened only with water and mild soap. Never let any liquid get inside the tool; never immerse any part of the tool into a liquid.

Operation

Set Up

This nailer is designed to be used without oil.

- Before you use the nailer, be sure that the compressor tanks have been properly drained.

- Wear proper eye, hearing and respiratory protection.

- Lock the magazine release in the back position and remove all fasteners from the magazine.

- Check for smooth and proper operation of contact trip and pusher assemblies. Do not use tool if either assembly is not functioning properly. NEVER use a tool that has the contact trip restrained in the up position.

- Check air supply. Ensure that air pressure does not exceed recommended operating limits; 70 to 120 psi, (4.9 to 8.3 bar, 5 to 8.5 kg/cm2).

- Connect air hose.

- Check for audible leaks around valves and gaskets. Never use a tool that leaks or has damaged parts.

Inspection

Before you start using the stapler you are expected to do an initial inspection and access its readiness for use. Consult the checklist at the end of this document as well as the detailed processes here.

Loading

⚠️Release the trigger and contact trip.

⚠️Detach the air supply.

- Read all Safety Warnings before using tool.

- Connect the tool to air supply.

- Push the magazine release (F) and slide magazine (E) to open chamber.

- Position nailer on a stable surface so contact trip is pointing upward and away from you.

- Insert fasteners into the chamber.

- Slide magazine until it clicks, securing the magazine.

General Operating Instructions

The tool can be actuated using one of two modes: single sequential action trigger mode and bump action trigger mode.

Sequential action trigger - Red trigger

The sequential action trigger’s intended use is for intermittent fastening where very careful and accurate placement is desired.

To operate the nailer in sequential action mode:

- Depress the contact trip firmly against the work surface.

- Pull the trigger.

A fastener will be driven each time the trigger is pulled as long as the contact trip remains depressed which could result in accidental driving.

Bump action trigger - Black trigger

The bump action trigger’s intended use is for rapid fastening on flat, stationary surfaces.

Using the bump action trigger, two methods are available: place actuation and bump actuation.

To operate the tool using the place actuation method:

- Pull the contact trip against the work surface.

- Pull the trigger.

To operate the tool using the bump actuation method:

- Pull the trigger.

- Push the contact trip against the work surface. As long as the trigger is pulled, the tool will drive a fastener every time the contact trip is depressed. This allows the user to drive multiple fasteners in sequence.

Adjusting Depth

⚠️Release the trigger and contact trip.

⚠️Detach the air supply.

The depth that the fastener is driven can be adjusted using the depth adjustment next to the trigger of the tool.

- To drive the fastener shallower, rotate the depth setting wheel (J) to the right.

- To drive a fastener deeper, rotate the depth setting wheel (J) to the left.

Consumables

Staples are consumables. They may be purchased at the Protohaven shop or you can bring your own. This tool can accept:

- 18 Gauge, 1/2“ – 1-1/2” (12.7 mm – 38.1 mm) length, 1/4“ (6.4 mm) crown staples

Maintenance Requests

If you encounter any of the issues listed in the Inspection area or have any other issues with the printer not working properly

- Update the physical Maintenance Tag at the machine

- 🟢Green can be used without issue

- 🟡Yellow can be used withcaution

- ⛔Red cannot be used without hazard to either the user or the equipment

- Record issues at protohaven.org/maintenance. This notifies our staff and volunteer maintenance crew of any issues.

Troubleshooting

Clearing Jams

- Disconnect the tool from the air supply.

- Push the magazine release (F) and slide magazine to open chamber.

- Position stapler on a stable surface so contact trip is pointing upward and away from you.

- Remove all fasteners in the top chamber of the magazine.

- Remove bent fastener, using pliers if necessary.

- If driver blade is in the down position, insert screwdriver or other rod into nosepiece and push driver blade back in position.

- Reinsert fasteners into the top chamber of the magazine (see Loading the Tool).

- Slide magazine until it clicks, securing the magazine.

- Reattach air supply.

NOTE: Should fasteners continue to jam frequently in nosepiece, have tool serviced by an authorized PORTER-CABLE service center.

| Problem | Likely Cause | Potential Solution |

|---|---|---|

| Trigger valve housing leaks | O-ring or valve stem failure | Replace valve using: Trigger Valve Kit |

| Top cap leaks air | Loose cap screws | Tighten cap screws using appropriate hex wrench |

| Damaged or worn gasket or o-ring | Replace gasket/o-rings using: O-ring Repair Kit | |

| Exhaust leaks | Main seal or o-ring damaged, debris in tool | Replace gasket/o-rings using: O-ring Repair Kit |

| Air leaks around nose when tool is at rest (Driver blade in up position) | Damaged or worn o-rings | Replace gasket/o-rings using: O-ring Repair Kit |

| Air leaks around nose when tool is in actuated position (Driver blade in down position) | Damaged or worn bumper | Replace bumper using: Bumper Kit |

| Tool does not cycle in cold weather | Tool not receiving air | Check air supply |

| Valve may be frozen | Warm up tool | |

| Damaged or worn o-rings | Replace gasket/o-rings using: O-ring Repair Kit | |

| Broken or damaged driver blade | Replace Driver Blade Kit | |

| Lack of power; sluggish | Low air pressure | Check air supply |

| Damaged or worn o-rings | Replace gasket/o-rings using: O-ring Repair Kit | |

| Exhaust port blocked or clogged | Disconnect the tool from the air supply, remove exhaust plate from top of tool, clean port | |

| Skipping fasteners; intermittent feed | Air restricted | Check air supply and couplers |

| Nosepiece screws loose | Tighten nosepiece screws using appropriate hex wrench | |

| Wrong size/angle fasteners | Use only recommended fasteners | |

| Dirty magazine | Clean magazine track and nosepiece | |

| Worn magazine | Replace magazine | |

| Broken or damaged driver blade | Replace Driver Blade Kit | |

| Trigger valve o-ring worn or damaged | Replace valve using: Trigger Valve Kit | |

| Worn or damaged pusher spring | Replace spring | |

| Magazine loose | Check that magazine latch is holding firmly | |

| Fasteners jam in tool | Driver channel in nose piece worn | Replace nosepiece |

| Wrong size/angle fasteners | Use only recommended fasteners | |

| Magazine loose | Check that magazine screws are holding firmly | |

| Worn driver blade | Replace Driver Blade Kit | |

| Nosepiece screws loose | Tighten nosepiece screws using appropriate hex wrench | |

| Fasteners not feeding properly | Ensure fasteners are feeding properly into nose |

Additional Resources

Staff Use

| ⚠️ AUTHORIZED MAINTENANCE GROUP ONLY |

If you are part of the maintenance group please log on to the #maintenance channel of our Discord server to:

- Perform a Maintenance Action

- Request a Maintenance Purchase

- Review complete Maintenance Logs for each machine

- Generally chit-chat about maintenance

Tools

The following should be in a Maintenance tool kit for the….

- item1

- item2