Table of Contents

CNC Micro Mill (Othermill)

- Manufacturer: Bantam Tools

- Model: PCB Mill

- Manual: Support Site

- Clearance Required: PCB Mill

Othermill is a desktop CNC milling machine. Use Othermill to create custom circuit boards, product prototypes, and other 3D objects.

The Tool Safety, Tool Care, Operation, section of this guide are what instructors use to ensure that you can use the equipment according to community expectations.

Requirements

PCB Mill clearance or class equivalent is required before use.

Warnings

- ⚠️Operators must supervise the Othermill whenever it is in use.

- ⚠️Operators must vacuum and clean the Othermill after each use.

- ⚠️Operators should wash their hands after use.

- 🚫Do not use unapproved materials in the mill. Ensure your PCBs are FR-1

- 🚫Do not let the Othermill operate unattended.

- 🚫Never put your hand near moving machinery, make sure to allow the machine to stop fully before trying to work inside the chamber.

See the Safety Section for more information..

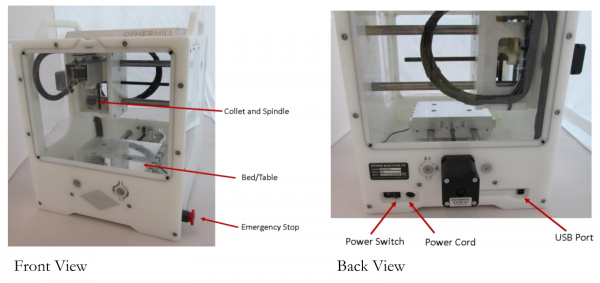

Tool Anatomy

Othermill

- Emergency Stop - If the machine starts operating in a dangerous or unexpected way this button on the right front side will stop the machine.

- Power Switch - On the right side on the back bottom next to the power cord.

- Power Cord Port - The port for the power supply.

- Spindle - The electric motor that spins the end mills.

- Cullet - Clamp that holds the bits and end mills it’s a ⅛” collet.

- Cullet Wrenches - Not Pictured, the wrenches sit in pockets secured by magnets on the top of the othermill.

- USB Port - USB Type A port on the back of the Othermill connects to a PC running the Bantam Desktop CNC software.

- Safety Panels - Clear Acrylic panels that attach magnetically to the sides of the machine to keep dust and debris in.

- Bed / Table - Machined plate your workpiece is attached with double sided tape.

End Mills and Bits

🧩 Protohaven does not provide end mills and engraving bits for the Othermill. Members are to bring their own. They are easily broken. And using community end mills of unknown sharpness is simply not a good practice. End mills and bits can be purchased from your seller of choice or from Bantam Tools if you want ones that the tool paths are calibrated for.

The Othermill has a 1/8 “ Collet The following end mills and bits are appropriate to use on the Othermill.

- Ball End Mill, 1/8“

- Ball End Mill, 1/16”

- Flat End Mill, 1/8“

- Flat End Mill, 1/16”

- Flat End Mill, 1/32“

- Flat End Mill, 1/64”

- Metal Engraving Bit, 0.005“

- PCB Engraving Bit, 0.005”

Tool Tray

The Tool Tray for the othermill contains the following items:

- Safety Glasses

- Double Sided Tape

- Small Paint Brush

- Scraper

- Digital calipers

- Collet Wrenches (Attached to top of Othermill)

- Tool Safety

- Eye Protection

Tool Safety

Eye Protection

Even though the othermill has a window that encloses the work area when running eye protection is still required for those operating or observing the operation of the Othermill.

Cut and Crush Risk

Keep your hands and fingers out of the enclosure when the machine is running, wait for it to come to a complete stop before removing the guards and accessing the machine. This also means no cutting fluid or other coolant/lubrication.

Speeds and Feeds

Part of safety is to understand appropriate feeds and speeds for your particular end mail and material. The Bantam software will control the feed rates based on material and bit selection. Check out the links below to see what are recommended for various materials.

Permitted Materials

It’s important that you only use permitted material in the Othermill

- ✅ FR-1 or FR-2 printed circuit board blanks (not FR-3,4)

- ✅ Linoleum

- ✅ ABS

- ✅ Acrylic

- ✅ Brass (C360 alloy / free-machining)

- ✅ Aluminum (6061 alloy)

- ✅ Hardwood (e.g., mahogany)

- ✅ Soft stone (e.g., soapstone)

- ✅ Silver (for engraving)

- ✅ Leather (for engraving)

The following materials are not permitted.

- 🚫FR-3 or FR-4 PCB boards (fiberglass hazard)

- 🚫 Carbon Fiber

- 🚫 Steel, stainless or otherwise

- 🚫 Iron

- 🚫 Magnesium

- 🚫 Titanium

- 🚫 Lead

- 🚫 Aluminum or Brass of unknown alloy

- 🚫 Fiberglass

- 🚫 Hard stone and precious gems

- 🚫 Glass

- 🚫 Silver chloride or other powdery materials

- 🚫 Chocolate, cheese, or other food products

Tool Care

Inspection

Before you start using the Othermill you are expected to do an initial inspection of it and access its readiness for use. Consult the checklist at the end of this document as well as the detailed processes here.

Make sure your machine is clean. Use a good vacuum after each milling job to remove as much of the resulting material debris (called swarf, which is just the best word ever) in and around the machine as possible. Use a small paint brush to loosen any debris that accrues around the inside of the spindle housing.

Before and after milling, inspect the six metal rods. These rods, also called rails or ways, hold up the carriages in the milling machine. Make sure the rails and the bed are clear of dust, tape, or glue, and make sure you have a tidy working environment. Sticky substances on the rails can cause the machining bed to dislodge the rails from the frame and will impact your milling project.

🧩 Note the left side panel, the one with the honeycomb engraved on it. It’s missing the factory magnet that activates the safety lockout on the enclosure. There is a small magnet glued to the inside that satisfies the lockout. If the software is saying that a safety panel is open but all 4 panels look ok then this magnet might have come loose. Dull and Worn out end mills and bits Keep track of all cutting tools in order to know how long they’ve been in service. A dull end mill will make fuzzy or jagged cuts and can cause the machine to cut incorrectly. Old tools are also more likely to break while cutting.

Maintenance Requests

If you encounter any of the issues listed in the Inspection area or have any other issues with the printer not working properly

Update the physical Maintenance Tag at the machine

- 🟢Green can be used witVacuumhout issue

- 🟡Yellow can be used with caution

- ⛔Red cannot be used without hazard to either the user or the equipment

Record issues at https://protohaven.org/maintenance. This notifies our staff and volunteer maintenance crew of any issues

Operation

Software Setup

Download and install the Bantam Tools Desktop Milling Machine Software

The Bantam Tools software is the application that controls the Othermill. Load your design files into the Bantam Tools software and the program will figure out the most efficient toolpaths to complete yoru milling project. You can use the Bantam Tools software on any of the Makerspace laptops, or you can download it on your own computer.

Compatible File Formats

- Bantam Tools Desktop Milling Machine Software supports files from many popular design tools:

- Vectors (.svg)

- EAGLE (.brd)

- Gerbers

- G-code (.nc, .tap, .gcode)

Bantam Tools Desktop Milling Machine Software is free and can be used without any hardware. So load up your files and see what it would look like to mill them.

PCB Design Considerations

You need to have enough space between the components on your board that the OtherMill’s tool can cut between them. For example, if you’ll be using a 1/32“ endmill, your traces, pads, vias, etc. need to be larger than 0.03125” apart.

You can use smaller tools, like a 1/64“ endmill, which will allow you to place objects closer together. Use large tooling whenever possible to complete the job more quickly. Note, smaller bits are more prone to breaking.

If you’ll be using surface-mount (SMD) components, the pads need to have enough space between them for the tool to fit. Check the SMD package compatibility list to make sure. If your package isn’t listed, you can test if it will work by making an EAGLE board file, importing it into Bantam Tools, and looking to see if there are cut lines between the pads.

If your board has vias (electrical connections between the front and back of the board), you’ll need to create a connection between them. The simplest way is to put a piece of wire in the via hole and solder both ends, but you can also use via eyelets (aka rivets), which sit neatly in the holes as you solder them. You can also use tinned wire, which you can thread through all the holes much more quickly than eyelets or individual bits of wire.

Your holes for pads and vias need to be large enough that your tool can drill them. If you’ll be using eyelets, your holes also need to be large enough for the eyelets to fit. Bantam Tools will render what it thinks the machine can cut. If it looks like something’s been left out, add a smaller tool or change element sizes.

You can have the autorouter avoid certain areas and not use through-hole pins on components as vias. This is handy when you are using components that can’t be soldered Recommended settings Recommended settings (spindle speed, cutting feedrate, plunge rate, maximum pass depth) are on the Othermachine support site under the “Materials” section. Follow these closely. We speak from experience. Do not use CAM software that cannot customize these settings.

Milling settings are constrained by: Bit strength. Cutting material too fast or too deep will break bits, especially smaller ones. Spindle power. If the bit goes too deep, it may get stuck and stall the spindle. Material properties. Cutting too aggressively may cause the material to deform or melt, including onto the bit (which will break the bit). Fixturing strength. The workpiece may get flung loose from the table, especially if using only tape. Keep in mind that continuous cutting may heat up the material so much that the tape loosens just from the heat.

Setting up Othermill

- Ensure the other mill is clean and free of debris. Vacuum out any materials leftover from previous use;

- Plug the Othermil into a power outlet and connect it via USB to a computer, then turn on the machine;

- Open up the Bantam Tools software;

- Remove the safety window;

- Measure the thickness of your material accurately with digital calipers.

- In the Bantam Tools software, locate the fixturing, changing if necessary for your job;

- Set the material thickness that was measured.

- Affix your material to the Othermill base, using double-sided tape.

- Insert the correct end mill for your milling project:

- Use flat end mills for cutting 2D shapes like circuit boards, flat-sided 3D shapes, and for detail work

- Use ball end mills for cutting curves and 3D shapes into woods, waxes, and plastics

- Use engraving bits for fine detail work

- Put the safety windows back into place.

- Start the job and monitor the machine as it cuts..

🧩 When you are trying to remove a bit from the collet there is a trick to it. Loosen the nut with the wrenches then it will spin free 2 or 3 turn and stop. The bit will still be firmly held in place. Use the wrenches again to open the nut more. Hold the endmill while you’re doing this. The nug will give way and the end mill will drop. It could break a small one so make sure you have a finger on it. Fixturing Or how you affix your workpiece to the bed. There are several options beyond the directions to use Scotch 3m double sided tape. There is also heavy-duty Nitto Permacel P-02 double-sided tape which is said to stick better

For even more fixturing power, apply hot glue around the edges of the material (never under, otherwise the material will be much taller than expected). Keep in mind that hot glue is hot and will melt many plastics. Avoid cutting through hot glue; it will melt onto bits.

Extreme fixturing can be accomplished by removing the spoilboard entirely and bolting your piece into the slots in the bed. You will probably not need this.

Locating the tool tip Check out this guide on the Bantam site for how to locate / determine the length of the too.

Longer running jobs

For longer milling jobs, every 30 minutes, pause the job and vacuum out the machine. Use a small brush to loosen the debris, and then use the vacuum to remove the debris. Focus on the rails, the limit switches, and the linear bearings. The linear bearings are the circular pieces that the rails pass through. There are four linear bearings in each axis, so 12 total in the milling machine. To pause the job, you can either press the pause icon in the software or just pull one of the four windows off of the machine. Cleanup Always use the cleanup wizard in the Bantam software. Remove end mill from machine, return collet wrenches. Use the spatula to remove the work piece from the bed. Clean tape and residue from spoilboard Vacuum out any materials leftover from previous use; Put Safety windows back into place

CAM

CAM is the process of going from a CAD model to machine-specific instructions on where to put the tool (in this case, Othermill G-code).

Otherplan (excluding the beta) can do its own CAM for PCBs (Gerbers or EAGLE .brd files) or for 2D cutting (from SVGs), including engraving. For anything else, you must (very carefully) generate G-code using external CAM software and load it into Otherplan.

We highly recommend Autodesk Fusion 360 for CAM. Othermachine has a tutorial on getting started in Fusion 360 here.

Special note: when generating toolpaths, make sure the tool does not go out of bounds. Otherplan will not catch the error and the preview will look correct, but your cut will silently end up offset and you will be confused and sad. Additional Resources Scotch Double Sided Tape FR-1 Copper Clad from Spark Fun FR-1 Copper Clad on Amazon Bantam Tool PCB Bit Bundle Amazon PCB Engraving Bits 1/32 endmill on Amazon PCB Probing Kit Fine Dust Collection https://www.noisebridge.net/wiki/Othermill_CNC Bantam Project Library Othermill ⅛ bit fan https://support.bantamtools.com/hc/en-us/articles/115001671594-Fusion-360-Tool-Library https://github.com/synthetos/g2/wiki

http://makerspace.engineering.nyu.edu/wp-content/uploads/2018/09/Othermill_Guide_Fusion360.pdf

Troubleshooting

Problem 1

lipsum sorem.

Additional Resources

Staff Use

| ⚠️ AUTHORIZED MAINTENANCE GROUP ONLY |

If you are part of the maintenance group please log on to the #maintenance channel of our Discord server to:

- Perform a Maintenance Action

- Request a Maintenance Purchase

- Review complete Maintenance Logs for each machine

- Generally chit-chat about maintenance

Tools

- Isopropyl Alcohol

- Lubricant: Break-Free CLP

Regular Maintenance

The below article talks about lubricating the rods. Replacing the z axis belts and updating firmware.

Firmware

Happens automatically when attached to the Bantam software.

Tramming

TODO

Hippocratic Oath

- Start with the Manual

- Ask questions

- Do no harm

- Know your limits

- Document your actions

CNC PCB Mill Checklist

- Ordered List ItemEnsure the other mill is clean and free of debris. Vacuum out any materials leftover from previous use and report improper cleaning on equipment log.

- Measure thickness of workpiece

- Affix your material to the Othermill base, using double-sided tape.

- Load and tighten end mill into collet.

- Set the appropriate material, size and thickness in the software for the workpiece

- Put the safety windows back into place and wear safety goggles.

- Start and monitor cut.

- After machine is no longer operating remove safety panel

- Pry workpiece off of the bed and remove all tape and residue.

- Vacuum inside of mill, use paintbrush to clean around spindle

- Ensure collet wrenches are back in their spots.

- Poweroff Othermill

- Return Tool Tray.