Table of Contents

Reflow Oven

- Model: T-962

- Manufacturer: Puhui

- Documentation: Original Manual

- Open Source Software: Unified Engineering Open Source Software

Prerequisites

Electronics Area Clearance

Warnings

🟢 The oven software has been replaced with the open source software from unified engineering. Consult that instead of the manufacturers manual.

⚠️ Solder may contain Lead, Always use proper ventilation or fume extraction when working with the soldering equipment. Flux vapors can also be irritating to people. Use in a well ventilated area

🚫Do not leave the reflow oven plugged in when not in use.

🚫Do not power off the oven until it has cooled.

⚠️Ensure that your components are safe to use in the oven

- Are highly reflective, like clock crystals can’t be headed by infrared light.

- Plastic terminals that can’t withstand 250C

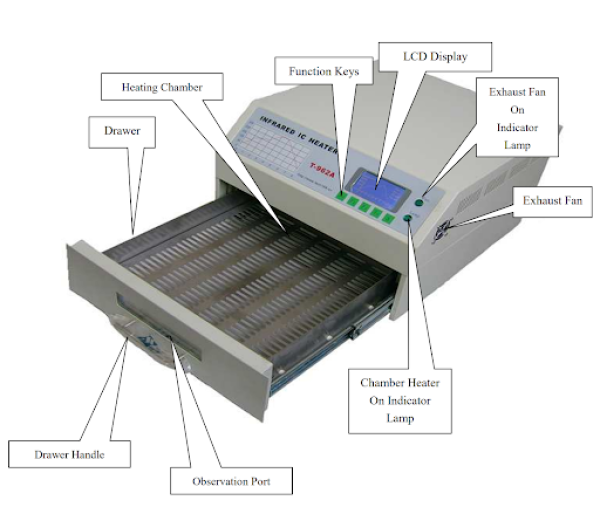

Tool Anatomy

Soldering Safety Guidelines

General Soldering Safety

- Turn the unit off or unplug it when not in use.

- Different boards and soldiers need different temperatures don’t start out too hot

- Give any soldered surface a minute or two to cool down before you touch it.

Work Safely with Solder, Flux, and Cleaners

- Use lead free solder paste

- Keep cleaning solvents in dispensing bottle to reduce inhalation hazards.

- Always wash your hands with soap and water after soldering.

- Read and understand the MSDS (Material Safety Data Sheets) for all materials before beginning work (e.g., http://jr.chemwatch.net/chemwatch.web/account/login).

Dangers of Lead Exposure

Lead (http://www.cdc.gov/niosh/topics/lead/) on your skin can be ingested and lead fumes can be given off during soldering. Other metal (https://www.osha.gov/SLTC/metalsheavy/index.html) fumes can also be hazardous. Lead can have serious chronic health effects, such as reproductive problems, digestive problems, nerve disorders, memory and concentration problems, muscle and joint pain.

Avoid Toxic Fumes

Work in a well‐ventilated area, to prevent the mildly caustic and toxic fumes from building up and causing eye or throat irritation.. The smoke formed is mostly from the flux which can be irritating, a sensitizer and aggravates asthma. Avoid breathing it by keeping your head to the side of, not above, your work.

Reduce Risk From Electricity

Always use a grounded outlet and grounding prong to reduce the risk of electrical damage if a short circuit occurs in the equipment.

Fire Prevention

Work on a fire‐proof or nonflammable surface that is not easily ignited. Never leave flammable items (such as paper) near the reflow oven. Know where your fire extinguisher is and how to use it.

First Aid

Immediately cool the affected area under cold water for 15 minutes. Do not apply any creams or ointments. Cover with a band‐aid. Seek medical attention if the burn covers an area bigger than 3 inches across.

Waste

- Discard lead and silver solder and dross in a container with a lid.

- Label the container: “Lead (Silver) Solder Waste for Recycling”.

- Used solder sponges and contaminated rags must be disposed of as hazardous waste.

- Keep a lid on waste solder containers when not adding or removing material.

Tool Care

Inspection

- Ensure that the cables are in good shape and the insulation is not broken or fraying.

- Ensure your workspace is clear from debris and clutter.

- Place this machine on an even surface with good ventilation and no combustible items nearby.

- Make sure to leave adequate space in front of the machine for opening the drawer.

- Leave at least 20 mm on either side because the machine will emit heat when in use.

- Ensure the power selector switch on the power supply is set to the 110V setting.

Cleaning

- Always keeps the drawer clean

- Clean the observation window of the drawer periodically.

- Wipe down the work area with a damp cloth and dispose of all scraps.

Maintenance Requests

If you encounter any of the issues listed in the Inspection area or have any other issues with the printer not working properly

Update the physical Maintenance Tag at the machine 🟢Green can be used without issue 🟡Yellow can be used with caution ⛔Red cannot be used without hazard to either the user or the equipment Record issues at https://protohaven.org/maintenance. This notifies our staff and volunteer maintenance crew of any issues

Tool Operation

Consult the Unified Engineering Wiki for information on how to use the firmware. https://github.com/UnifiedEngineering/T-962-improvements/wiki

⚠️Ensure that your components are safe to use in the oven

- Are highly reflective, like clock crystals can’t be headed by infrared light.

- Plastic terminals that can’t withstand 250C

Additional Resources

Staff Use

⚠️ AUTHORIZED MAINTENANCE GROUP ONLY

If you are part of the maintenance group please log on to the #maintenance channel of our Discord server to:

Perform a Maintenance Action Request a Maintenance Purchase Review complete Maintenance Logs for each machine Generally chit-chat about maintenance

Every Walkthrough

⚠️Ensure the reflow oven is off and unplugged when not in use. Especially when closing up for the night.

Regular Maintenance

Mods

This oven has a series of community mods that improve it’s performance and safety

We should check the oven to see if the tape has been replaced and the ground has been fixed.

we should consider if we install the open source firmware and install the temperature sensor for better performance.

Hippocratic Oath

- Start with the Manual

- Ask questions

- Do no harm

- Know your limits

- Document your actions