Table of Contents

Consumer Sewing Machine (Please Check)

- Model: Heavy Duty 4423

- Manufacturer: Singer

- Manual: PDF

Tool description

The Tool Safety, Tool Care, Operation, section of this guide are what instructors use to ensure that you can use the equipment according to community expectations.

Requirements

Consumer Multi-stitch Clearance or Class Equivalent Required Before Use

Warnings

🚫 Do not push or pull material while stitching.

⚠️ Power off the machine before threading, inserting the bobbin, or handling the needle. ⚠️ Keep fingers away from all moving parts!

See the Safety Section for more information.

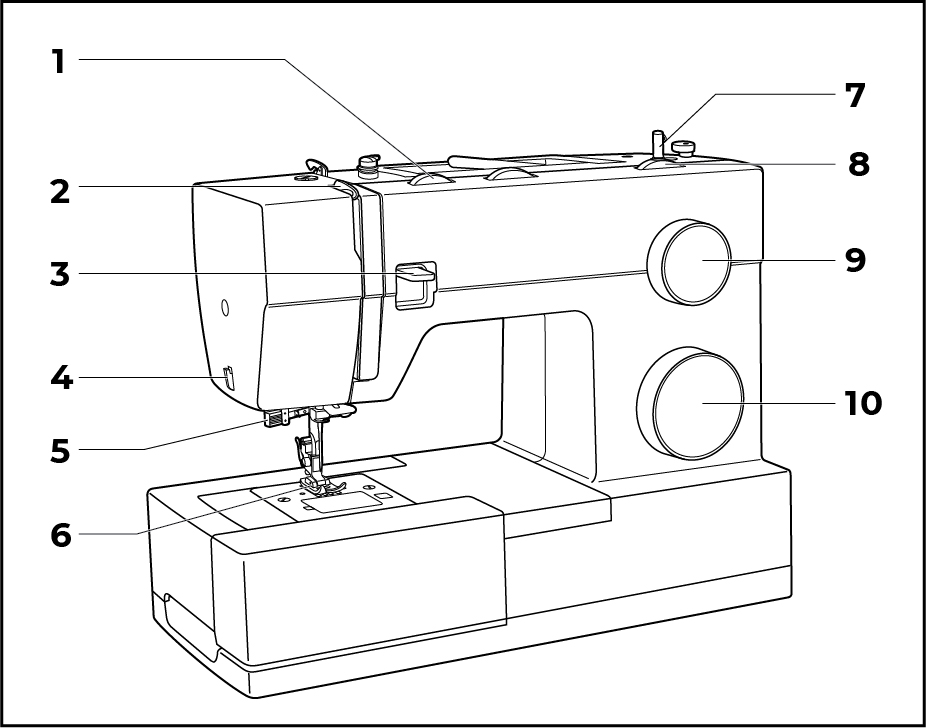

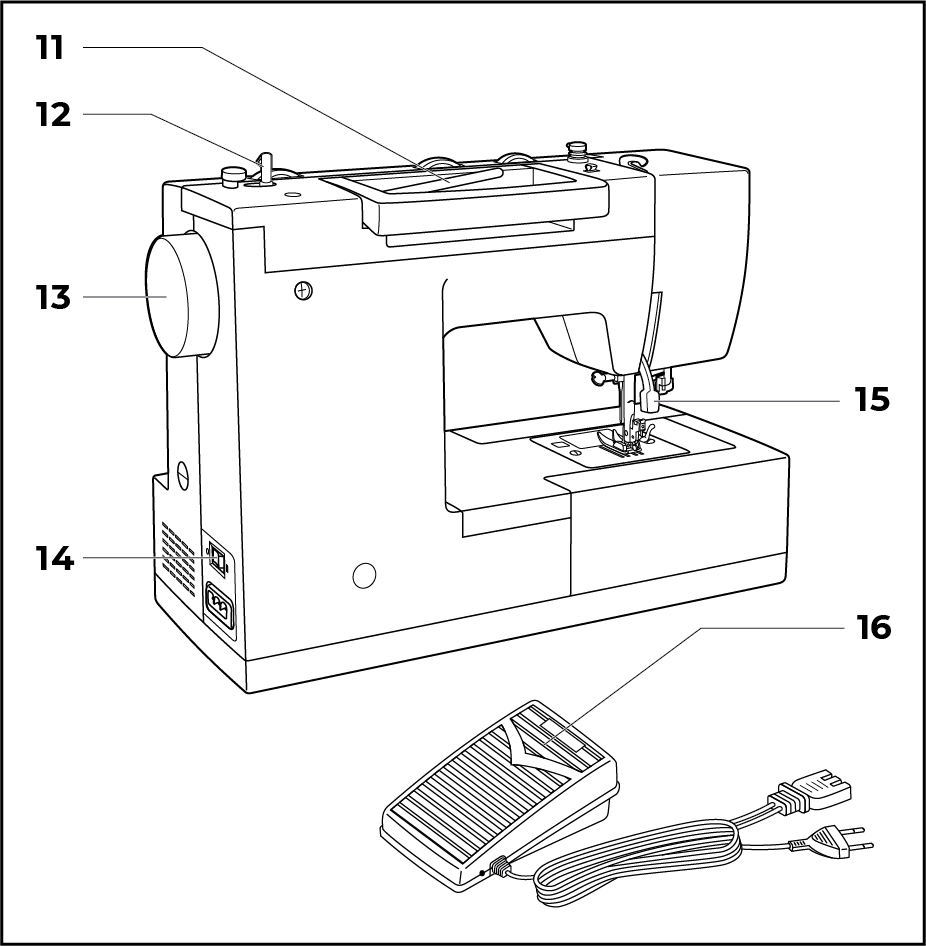

Tool Anatomy

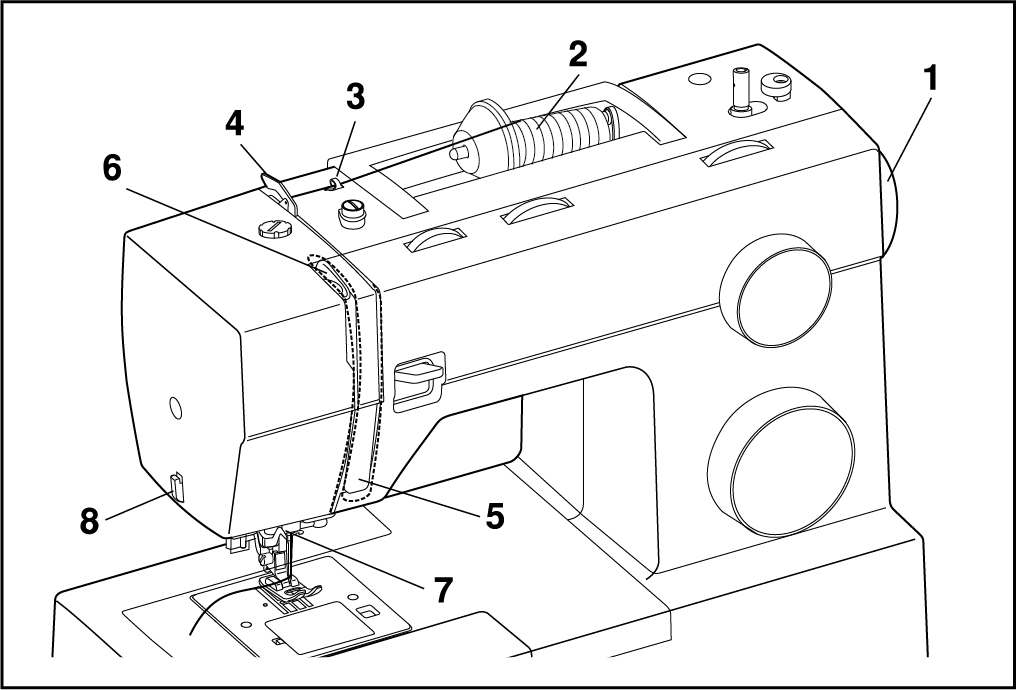

BASIC MACHINE ANATOMY

- Thread tension dial - regulates the tension of thread from the spool

- Thread take-up lever - part of the thread feeding mechanism that pulls thread off the spool

- Reverse sewing lever - engages the machine to sew in reverse

- Thread cutter - an attached tool to cut threads after stitch has been completed

- Presser foot - holds materials to be stitched to the bed

- Bobbin winding spindle - pin that holds the bobbin during bobbin winding

- Stitch width dial - adjusts the width of a stitch

- Stitch length dial - adjusts the length of the stitch

- Pattern selector dial - adjusts the type of stitch

- Automatic threader - needle threading tool

- Horizontal spool pin - holds the spool for the top thread

- Bobbin winding spindle - pin that holds the bobbin during bobbin winding

- Handwheel - manually advances the machine (turn counter clockwise only!)

- Power and light switch - on/off switch

- Presser foot lifter - lever that raises and lowers presser foot

- Foot pedal - controls the speed

Tool Safety

Common Hazards

The most common hazards are thread jams and broken needles.

- Watch for top thread and/or bobbin thread to bind up, jam, and birds nest.

- Avoid pulling/pushing fabric, which may misalign needles and cause breakage.

The most significant hazard is injury

- Always power off the machine before threading, clipping out jams, or replacing broken needles.

- Keep fingers away from all moving parts.

- Special care is required around the sewing machine needle.

Prohibited Materials

Thread Jams and needle breakage are critical concerns. Material that is too thick or rigid will lead to needle breakage. Material that is too slick (plasticized or otherwise “finished”) will slide against the presser foot and cause thread jams and/or needle breakage.

For those reasons, it is important to avoid:

- Abrasives

- Leather

- Heavy Weight Canvas

- Plastics

- Rigid Material (non-fabric)

- Rubber

- Vinyl

If you’d like to work with material beyond what the Singer Heavy-Duty is rated for, please refer to our Industrial Sewing Machines.

Initial Setup

SETUP CHECKLIST

- Wind the bobbin

- Ensure the needle is usable, replace if needed

- Thread the needle (aka top thread assembly)

- Insert the bobbin

- Select the stitch type

- Set the stitch width

- Align test fabric

- Lower presser foot and begin operation

CONSUMABLES

Appropriate needles and bobbins are available in the consumables section of our store front. Both are sold individually for ease and convenience.

Members are reasonable for bringing their own thread and fabric.

- Needles: Singer 2020 70/9 or 110/18 9(70) 18(110)

Standard sharp needles. Sizes range thin to large.

- Bobbins: Singer Class 15

Transparent for ease of monitoring the amount of thread available during use.

- Thread & Fabric:

- Always use the same thread in the upper tension and in the bobbin.

- Light-medium weight fabrics are approved for use on this machine.

- For heavy weight fabrics, please refer to our Industrial Sewing Machines.

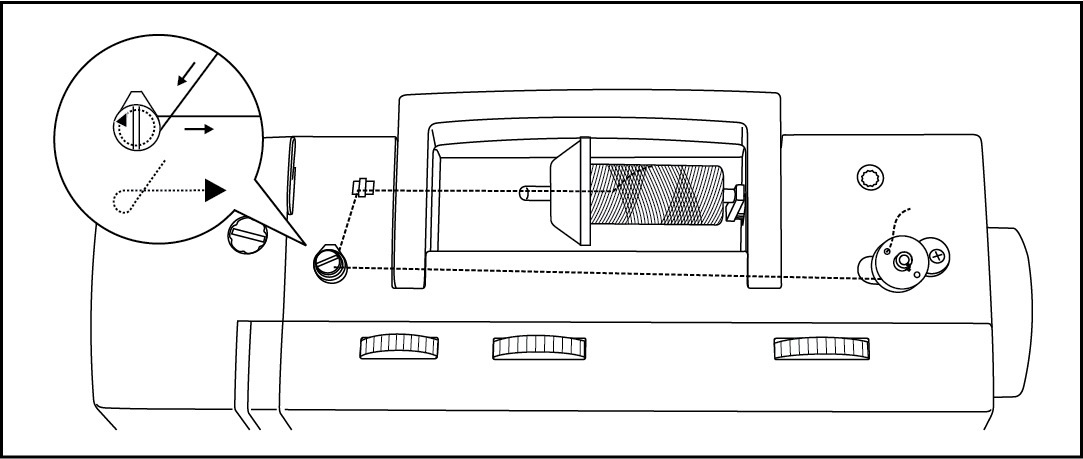

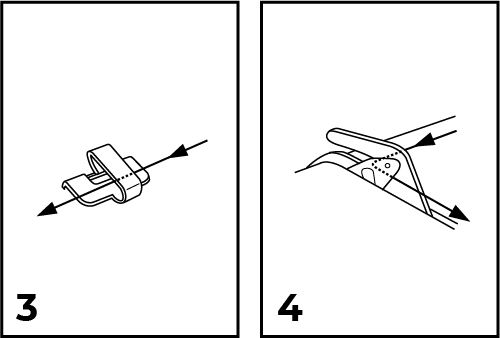

WINDING THE BOBBIN

Appropriate bobbins (singer class 15) are available in the consumables section of our store front.

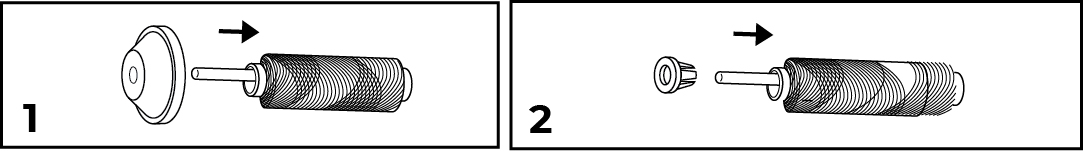

Load thread and corresponding spool holder onto the spool pin (1/2).

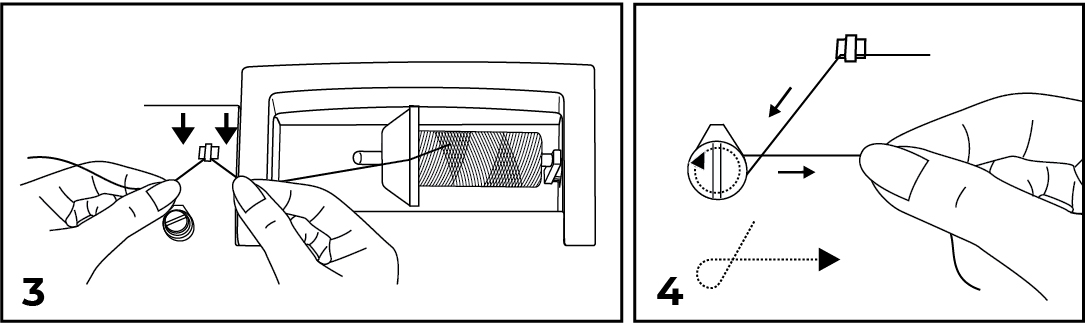

Gently snap the thread into the thread guide (3).

Then, wind the thread clockwise around the tension discs (4).

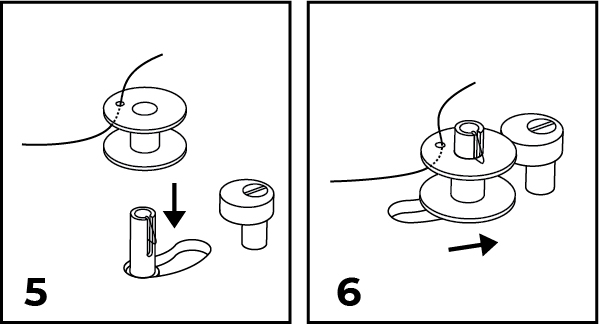

Thread the bobbin as illustrated (5) and place the bobbin onto the spindle.

Then, engage “bobbin winding mode” by gently pushing the bobbin to the right (6).

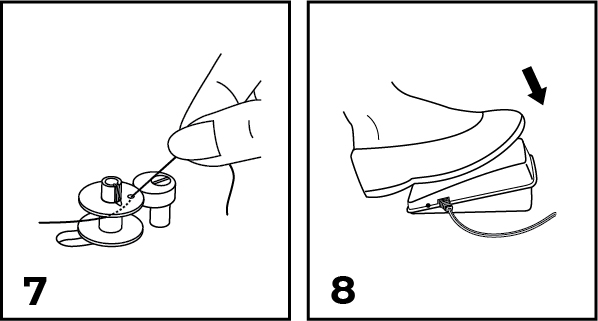

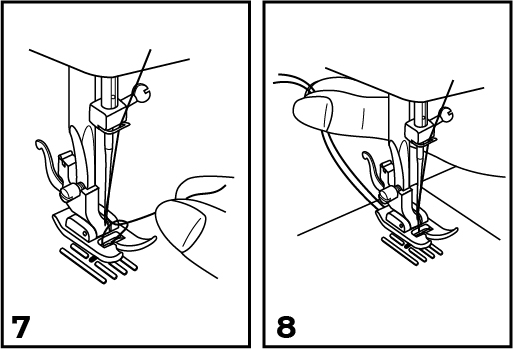

Hold the end of the thread (7) and step on the foot pedal (8) to begin winding.

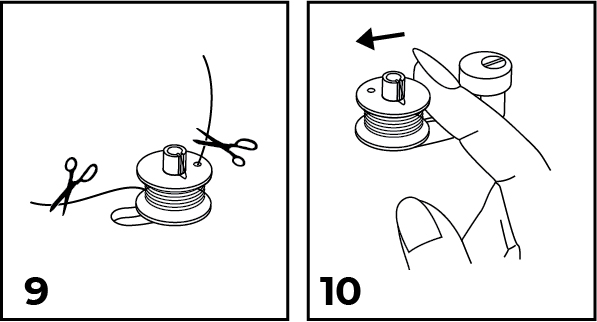

Cut the thread (9), disengage “bobbin winding mode” by pushing to the bobbin to the left (10), and remove the bobbin.

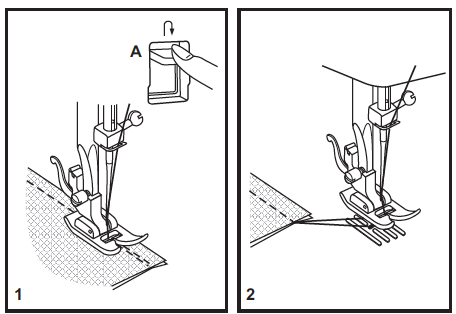

INSERTING THE BOBBIN

Ensure the power is off.

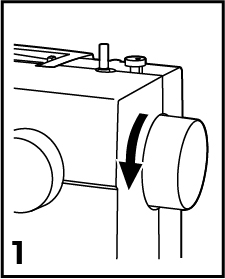

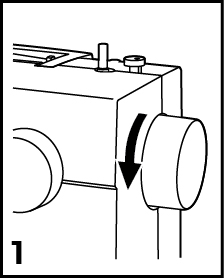

Turn the handwheel counterclockwise (1) until the needle is fully raised.

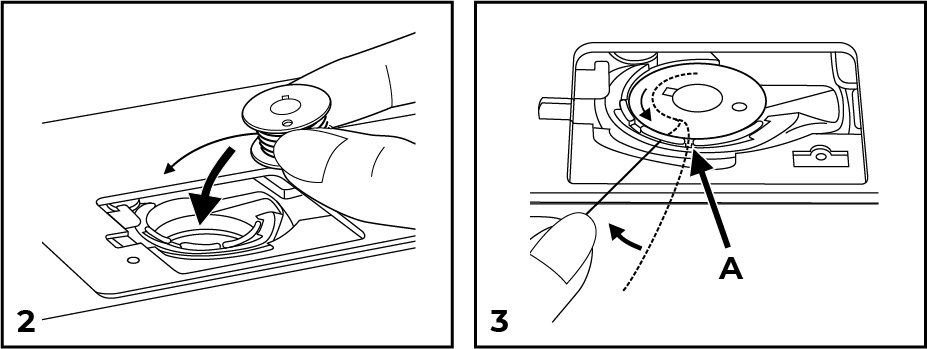

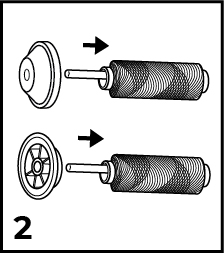

Insert the bobbin into the bobbin case (2) with the thread running counterclockwise.

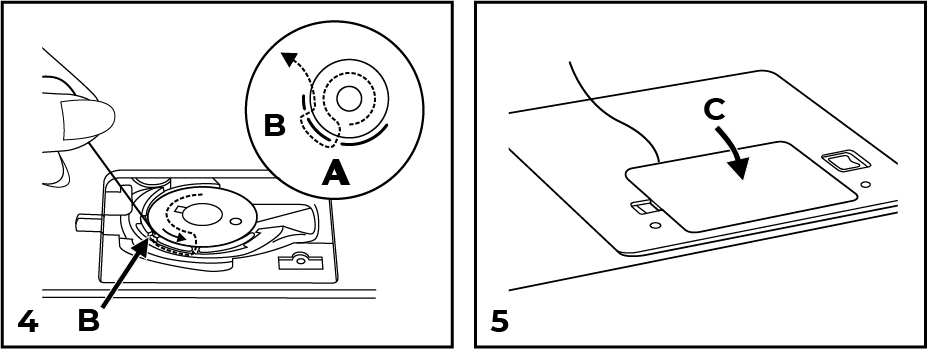

Then, pull the thread through slit “A” (3).

Draw the thread clockwise (4) until it slips into notch “B”.

Pull about 6 inches of thread and re-attach the bobbin cover plate.

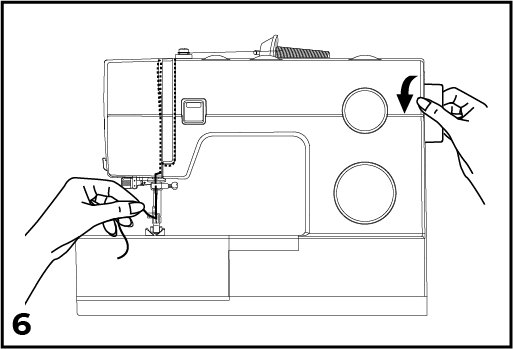

Hold the upper thread with the left hand while turning the handwheel counterclockwise (1). This will lower and then raise the needle.

Note: If it is difficult to raise the bobbin thread, check to make sure the thread is not trapped by the hinged cover or the Removable Extension Table.

Gently pull on the upper thread to bring the bobbin thread up through the needle plate hole.

Then, lay both threads to the back under the presser foot.

If the thread is looping or birdnesting on the top of the fabric, this is an indication that the bobbin thread has not been threaded correctly.

REPLACING THE NEEDLE

Appropriate needles (singer 2020 9(70) or 18(110)) are available in the consumables section of our store front.

- Power off the machine.

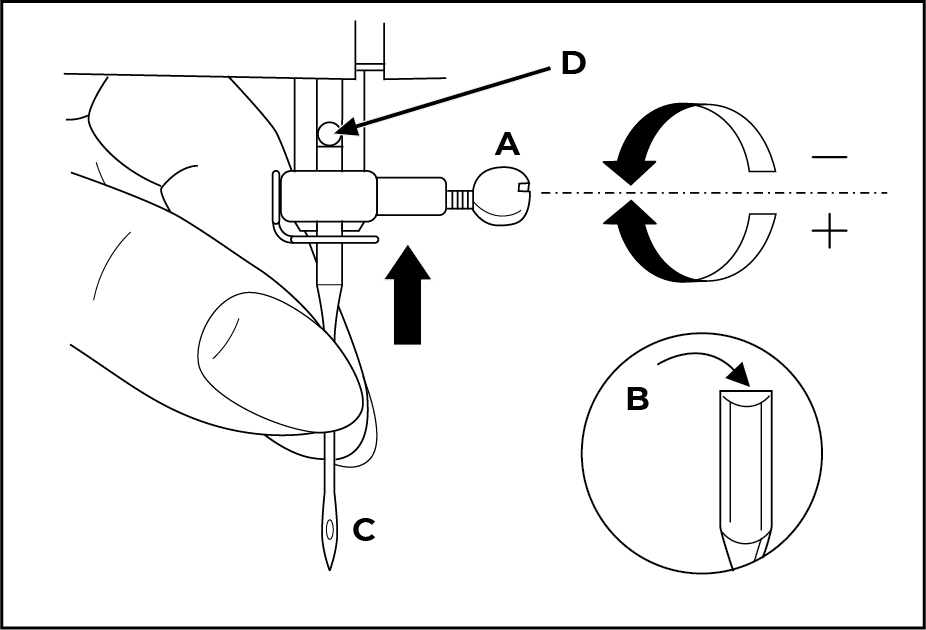

- Loosen the needle clamp screw (A) and re-tighten after replacing the needle.

- Ensure that the flat side of the needle shaft (B) is towards the back.

- Insert the needle as far up as it will go (C/D).

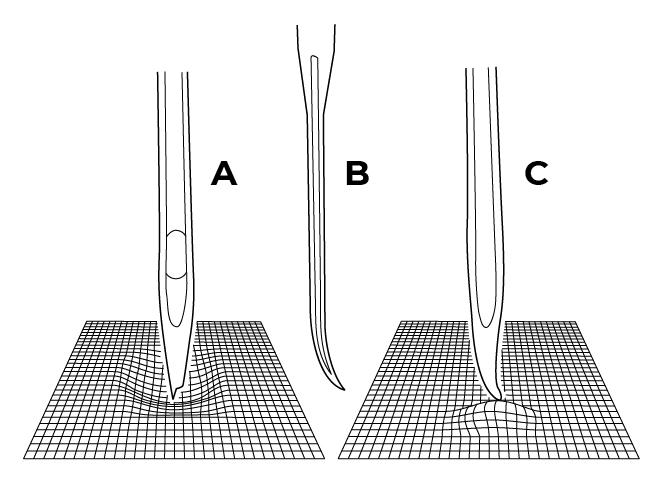

It is important to replace needles regularly. Problems can occur with:

A. Damaged points

B. Bent Needles

C. Blunt needles

THREADING THE NEEDLE

Ensure the power is off.

Turn the handwheel counterclockwise (1) until the needle just barely begins to descend.

Raise the presser foot to release the tension discs.

Lift the spool pin and place the spool of thread onto the holder (2).

Note: for small thread spools, invert the spool holder so that the small side is touching the spool of thread.

Pass the thread through the upper thread guide (3).

Then, pull the thread through the pre-tension spring (4).

Then, pull the thread through the pre-tension spring (4).

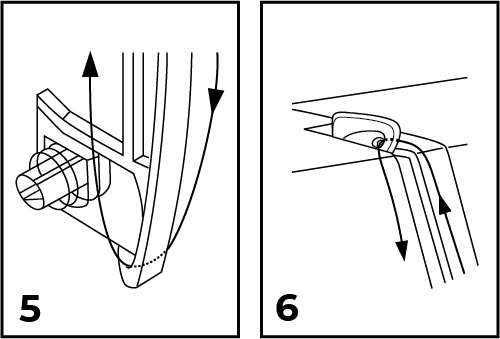

Draw the thread down the right channel and, then, up the left channel (5) to wrap the thread into the tension module.

Pass the thread from right to left through the slotted eye of the take-up lever and then downwards again (6).

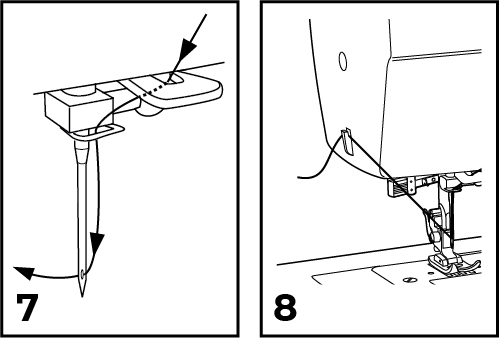

Pass the thread behind the thread guide and behind the wire clamp guide (7).

Then, pass the thread down and through the eye of the needle from front to back (7).

Pull about 6-8 inches of thread through the needle eye and trim (8).

Operation

- Setup the machine

- Test the stitch on scrap or similar fabric to what you will be sewing

- Adjust the tension and stitch length

- Remove test and trim threads

- Align project fabric

- Lower the presser foot

- Step on the foot pedal

- Back stitch/reverse to keep your stitch from unraveling

- Sew sew sew!

- Cleanup

ADJUSTING THE TENSION

Proper tension is critical for strong seams. The basic thread tension setting is “4”. 90% of all sewing will be between “3” and “5”, but each stitch type, thread, and fabric requires individual testing and adjustment.

To increase the tension, turn the dial to the next number up. To reduce the tension, turn the dial to the next number down.

BACK STITCH/REVERSE SEWING

To secure the beginning and the end of a seam, press down the reverse sewing lever (A). Then, sew a few reverse stitches.

Release the lever and continue sewing forward.

Cleanup

- Power off the machine and ensure all controls are set to the off (“O”) position.

- Unthread top needle and spool

- Remove bobbin

- Wipe down, vacuum, and blow out lint and stray thread clippings

- Sweep up threads, lint and debris and deposit in waste bins

Maintenance Requests

If you encounter any of the issues listed in the Inspection area or have any other issues with the tool not working properly:

- Update the physical Maintenance Tag at the machine

- 🟢Green can be used without issue

- 🟡Yellow can be used withcaution

- ⛔Red cannot be used without hazard to either the user or the equipment

- Record issues at protohaven.org/maintenance. This notifies our staff and volunteer maintenance crew of any issues.

Troubleshooting

Please note any maintenance needs or concerns on both the physical maintenance tag and protohaven.org/maintenance

| Common Issues | Possible Causes | Resolutions | |

|---|---|---|---|

| Thread is looping or birdnesting on the top of the fabric | Error in threading the bobbin. | Remove all fabric and thread. Then, rethread the machine and start again. | |

| Thread Jams | Error in threading top or bobbin thread | Remove all fabric and thread. Then, rethread the machine and start again. | |

| Inappropriate tension | Remove all fabric and thread. Then, rethread the machine and adjust tension +/- (test on scrap material) | ||

| Decorative stitch is puckering fabric | Tension is too tight | Remove all fabric and thread. Then, rethread the machine and reduce tension | |

| Broken Needle | Material is too thick | Remove all fabric and thread. Replace needle, rethread the machine, and reduce the amount of layers being sewn and/or use thinner materials. | |

| Dull/Bent/Improper Needle selection | Remove all fabric and thread. Replace needle and rethread the machine. Then, start again. |

Special Setups

BUTTON HOLES & BUTTONS

Buttonhole sewing requires the use of the buttonhole foot. To gain access, please notify staff for a special setup.

STRETCH STITCH

The stretch stitch patterns are indicated in blue on the pattern selector dial. To select these, turn the pattern selector dial to the desired pattern. Then, turn the stitch length dial to “S1”.

Additional Resources

Singer Tutorial: Threading the Bobbin

Singer Tutorial: Automatic Needle Threader

Sewing Master: Threading & Winding the Bobbin

Staff Use

Check Out Kit

- Foot Pedal

- All purpose foot

- Zipper foot

- Buttonhole foot

- Button sewing foot

- Seam ripper w/ lint brush

- Edge quilting guide

- Screw driver

- Thread spool caps

- Spool pin felt

- Auxiliary spool pin

| ⚠️ AUTHORIZED MAINTENANCE GROUP ONLY |

If you are part of the maintenance group please log on to the #maintenance channel of our Discord server to:

- Perform a Maintenance Action

- Request a Maintenance Purchase

- Review complete Maintenance Logs for each machine

- Generally chit-chat about maintenance

Tools

The following should be in a Maintenance tool kit for the….

- item1

- item2