Table of Contents

Natural Gas Soldering Torch (Incomplete)

A natural gas/oxygen torch produces carbon-free flames, (5120°F for natural gas), which is a good all-purpose system to solder metals together.

The Tool Safety, Tool Care, Operation, section of this guide are what instructors use to ensure that you can use the equipment according to community expectations.

Requirements

Jewelry Area Clearance or class equivalent required before use.

Warnings

Tool Anatomy

RED = GAS

GREEN = OXYGEN

A. Natural gas line opener valve - turns on the gas

B. Bronze gas valve - allows gas to flow to the torch

C. Oxygen tank valve - turns on the oxygen

D. Bronze oxygen valve - allows oxygen to flow to the torch

Striker

Striker

Tool Safety

Personal Protective Equipment

Clothing and closed-toed shoes (preferably boots) must be of natural materials that will burn quickly and not melt to skin (i.e. cotton, denim, leather).

Common Hazards

Fire & Burns

PROHIBITED MATERIALS

Operation

Inspection

Set Up

Turn on the gases:

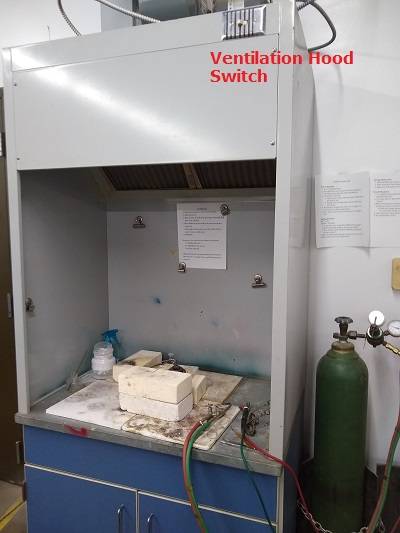

- Turn on ventilation hood

- Turn yellow knob (A) on gas line that's mounted on the wall from perpendicular (off) to parallel (on)

- Open bronze valve (B)corresponding to the torch you want to use. The big torch has big hoses, the mini torch has small hoses.

- Turn the grey Oxygen tank valve (C) to “Open”. It's the valve on top of the oxygen tank.

- Open bronze valve (D) that connects to the oxygen tank.

Lighting the torch:

- On the torch, turn on the GAS (RED) knob ¼ turn.

- Light the gas with a striker, do not use a lighter.

- Then introduce the OXYGEN (GREEN) by opening the valve slowly.

Note: If you open either the gas or oxy valve too much, it will blow itself out. Go slow, start small.

Turning off the torch:

- Close GREEN OXY valve on the torch FIRST

- Then close RED GAS valve on the torch

- Make sure both valves are closed when not in use!

Turn off the gases:

- Turn yellow knob on gas line (A) from parallel (on) to perpendicular (off)

- Turn grey valve on top of the oxygen tank (C) to “Closed”

- Bleed out all gas and oxygen from the hoses by opening the valves on the torch.

- Watch the oxygen gauges. When they both read “0”, close both valves on the torch.

- Close all bronze valves (B & D)

- Turn off ventilation hood

Soldering

- Make sure your piece is clean and free of debris

- Light your torch

- Burn off the alcohol in the firescale protection solution with torch

- Clip a chip of solder and use your flux and flux brush to paint it onto your solder seam

- SOLDER

- Remember if your piece has more than one solder joint, use HARD solder first, Use MEDIUM solder second, Use EASY solder last. (Hard solder tarnishes the least and has the closest color to the metal you are working with, so use hard if you just have one seam.)

Consumables

Some solder is located at the station, but users should be prepared to bring their own.

Cleanup

Maintenance Requests

If you encounter any of the issues listed in the Inspection area or have any other issues with the tool not working properly:

- Update the physical Maintenance Tag at the machine

- 🟢Green can be used without issue

- 🟡Yellow can be used with caution

- ⛔Red cannot be used without hazard to either the user or the equipment

- Record issues at https://protohaven.org/maintenance. This notifies our staff and volunteer maintenance crew of any issues.

Troubleshooting

| Common Issues | Possible Causes | Resolutions |

|---|---|---|

Additional Resources

Where can one find materials, tools, or other consumables (either local or online vendors)? What helpful video tutorials are there where one can dive deeper into operating this tool?

Staff Use

| ⚠️ AUTHORIZED MAINTENANCE GROUP ONLY |

If you are part of the maintenance group please log on to the #maintenance channel of our Discord server to:

- Perform a Maintenance Action

- Request a Maintenance Purchase

- Review complete Maintenance Logs for each machine

- Generally chit-chat about maintenance

Tools

The following should be in a Maintenance tool kit for the….

- item1

- item2